One in five garments in the world is cut by Lectra. So, when Le Boudoir Numérique was invited by the French company to visit its historic site of Cestas, it jumped on the train to Bordeaux to learn more about the factory that manufactures its automatic leather and textile cutting systems, dedicated to fashion, automotive and furniture. A factory like no other. A futuristic factory, based on the concept of Industry 4.0, as Eric Lespinasse, Industrial Director at Lectra explains.

By Ludmilla Intravaia

Le Boudoir Numérique: You have just given us a tour of Lectra's automatic cutting systems manufacturing site, a smart factory at the forefront of Industry 4.0. What is industrial manufacturing 4.0?

Eric Lespinasse, Industrial Director at Lectra: 4.0 is the idea of implementing automation, robotization, connectivity and the transfer of information for the benefit of a lower burden on humans . To do this, we have implemented several things, starting, at the end of 2018, with the AGV, the Automated Guided Vehicle, a small connected robot that moves, all by itself, and very simply, between the storeroom and the assembly lines (see our video below, AN). Sensors on the line signal a missing bin to the AGV control software, which sends the robot from the storeroom to the line to replace it, relieving humans of tiring back and forth movements. Since 2019, we have also been using QR codes to optimize trips to pick up parts from the storeroom, by indicating where they are exactly and the shortest route to get there. By taking fewer steps and making less effort, you gain efficiency and time, while ensuring that you always take the right item in the right place.

Besides its autonomous robot, does Lectra’s factory use other tools that work without human intervention?

Certainly. We have, for example, a scale which knows, in real time, the weight of the parts in its possession and, therefore, their quantities. Each time an operator takes parts, the scale registers it. Every two weeks, the scale calculates the difference in stock and orders the necessary parts on its own from the suppliers. Managing screws and small consumables is as daunting as it is essential, if you don't, you will quickly be in shortage. The idea of this connected supply chain is to free humans from this type of repetitive task for greater management autonomy.

Connected scale in Lectra’s factory, in Cestas, France, on September 7, 2021 (© Le Boudoir Numérique)

Is the tool dispenser installed at the entrance of the factory part of the same desire for teams autonomy?

Absolutely. Allowing an operator to use a tool has no added value. With this dispenser, he identifies himself with his badge to the machine which registers that he has taken a particular tool. The advantage is that the operator does not depend on his hierarchy to use tools, while the latter knows which tool has been removed. The teams are thus autonomous to take the tools they need, when they need them.

Assembly of the Vector cutting solution, dedicated to fashion, in Lectra’s factory, in Cestas, France, on September 7, 2021 (© Le Boudoir Numérique)

What other solutions have you deployed in your 4.0 strategy?

We have implemented DDMRP, Demand Driven Material Requirement Planning, namely the fact of no longer managing supplies and purchases, according to MRP II planning methodology, but on pull flows, on actual consumption. What I consumed yesterday, I am ordering today. We have also implemented the MES, Manufacturing Execution System which saves 5% of all manufacturing time, by automating administrative tasks to inform the production management system, thanks to barcode reading, for example. This is all part of the 4.0 deployment plan undertaken with my teams since 2017.

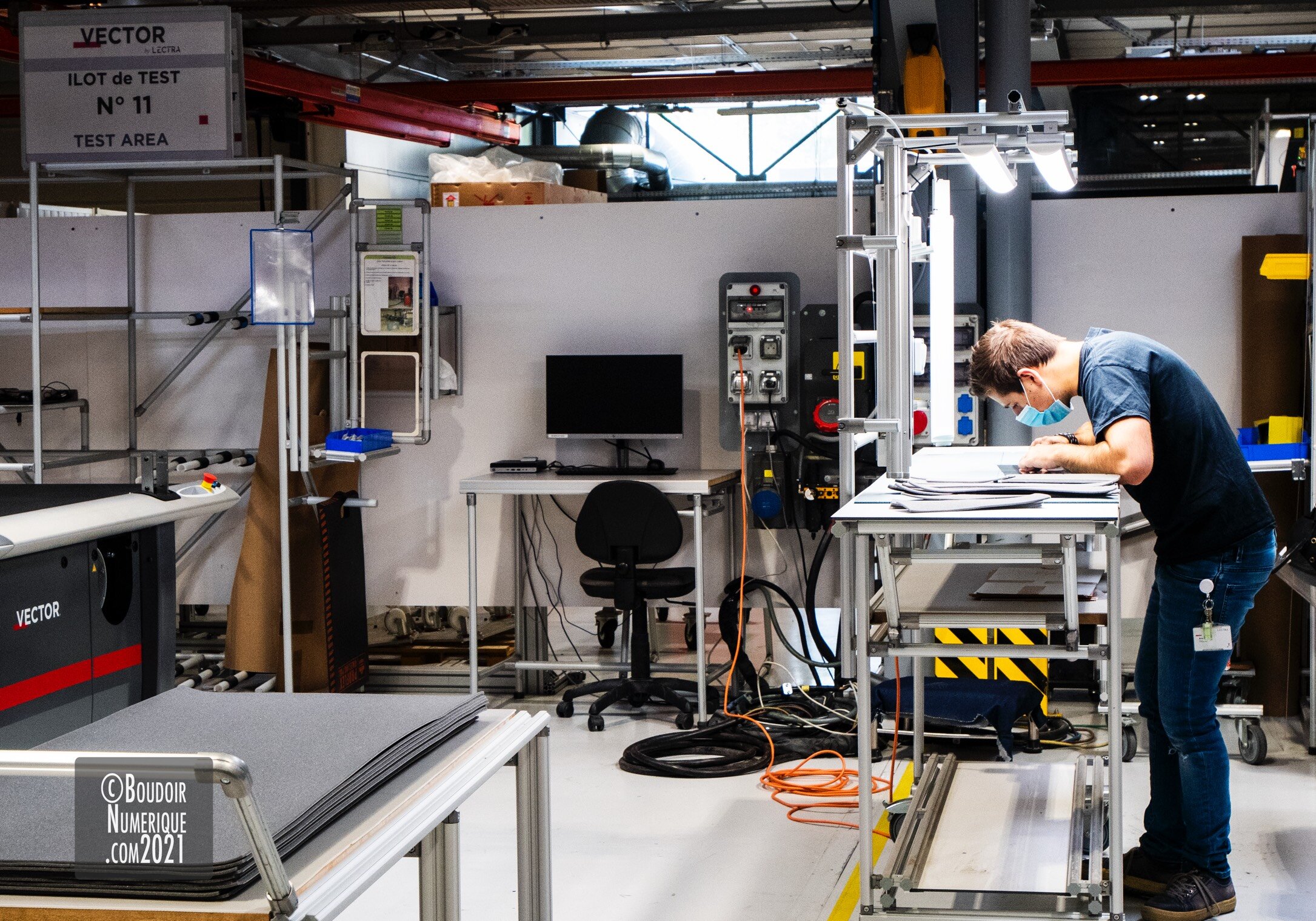

Test on Vector cutting solution, dedicated to fashion, in Lectra’s factory, in Cestas, France, on September 7, 2021 (© Le Boudoir Numérique)

You mentioned the role of connectivity in your smart factory. Without going into the details of Lectra's products, in particular Fashion On Demand by Lectra for the production of personalized fashion, can we say that the automatic cutting machines manufactured in Cestas are also 4.0?

Our machines are fitted with sensors that allow customers and our maintenance technicians to follow all the data about them in real time, the cutting and rotation speeds, the wear on blades and all consumables, etc., so much data for knowing how the machines are used, if they are used properly, if a machine requires the replacement of a part, in short, to control them remotely and take preventive measures, by anticipating technical problems . So, yes, they are 4.0 machines, in order to provide the best customer service.

Warehouse, in Lectra’s factory, in Cestas, France, on September 7, 2021 (© Le Boudoir Numérique)

* You don’t want to miss any fashion tech and beauty tech news ? It’s easy, subscribe to Le Boudoir Numérique newsletter !

* Continue reading with these following Boudoir Numérique articles :

- Meet the avatars of Tomorrow X Together in the virtual world of Ralph Lauren X Zepeto

- Olivia Rodrigo surfs on the aesthetics of augmented reality face filters with Apple

- Flame dress by Balmain - Olivier Rousteing signs a NFT dress for Vogue Singapore

- The virtual reality headset, fashion tech accessory at Balenciaga

- Cardi B revisits Tom Ford’s futuristic breastplate in Rumors, Lizzo's music video

- Augmented reality to try the Hermès scarf

- Pangaia unveils two innovative plant-based fabrics PLNTFIBER and FRUITFIBER

- The drag queen A'Whora wears a jacket in vegan alter-leather Piñatex

- Follow Vivienne, Louis Vuitton’s mascot, in the virtual universe of Louis The Game

- Louis Vuitton Horizon Light Up : This is not an UFO

- CMPT 3D - 3D printed sunglasses by Adidas X Marcolin

- Phantom by Paco Rabanne: This is not a robot

- Zepeto's avatars fall for Dior's virtual make-up

- Beauty tech mask from Lucibel.le Paris designed by Olivier Lapidus

- Delivery drones, smart home and fintech, the new normal dreamed by Khalid

- Exhibition Mode au futur : Focus on innovative textiles

- Spot, the Boston Dynamics' robot dances with the K-pop group BTS

- Spotted at VivaTech 2021 : Wood alter-leather shoes by Woowe